machine de broyeur de laitier de plomb à vendre

- concasseurs a cones de Svedala utilises

- rôle de l industrie de la pierre de concassage dans l usine de carrière de pierre en inde

- machine fil detirement pour le fer

- mise en place des equipements de manutention de materiau de sable

- concasseurs machoires occasion vendre en colombie britannique

- par le herbal rectifieuse en inde

- Velocidade do gás do moinho de cimento

- Concasseur à cône de rechange au RoyaumeUni

- fournisseur de broyeur de calcaire mobile malaisie

- what is capacity for jaw crusher 600x400

- information de conception de concasseur de contre attaque

- Haybuster Tub Grinder Craigslist

- vitesse de rotation critique concasseur

- broyeurs à charbon dans une centrale thermique

- prix des concasseurs de roche

Message en ligne

Concasseur à mâchoires - Concasseur à Mâchoires à Vendre

Concasseur à mâchoires font partie des équipements les plus importants de l’industrie minière et de la construction. Conçues pour écraser des blocs de roche et de minéraux de grande taille, ces machines robustes réduisent le matériel aux dimensions souhaitées avec une forte pression entre les mâchoires.

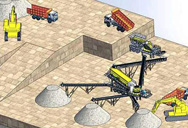

Concasseur mobile pour traitement de roche calcaire - Zenith

Les concasseurs mobiles jouent un rôle central dans le traitement du calcaire, offrant flexibilité, efficacité et production de haute qualité. Les concasseurs mobiles sont des unités de traitement autonomes montées sur des remorques ou des chenilles, offr

Combien de types de concasseurs de roche existe-t-il

Application: Les concasseurs de roches à mâchoires sont principalement utilisés pour briser des matériaux gros et durs en morceaux plus faciles à gérer, de sorte que les gens les utilisent souvent comme concassage primaire, et si vous avez des exigences élevées en matière de concassage de matériaux, vous devez préparer un concassage secondaire ou tertiaire.

Concasseurs de Pierres Dures Mobiles - Constmach

Le concasseurs mobiles de pierres dures est une solution parfaite pour concasser des roches très dures avec une abrasivité élevée et un rapport de silice (SiO2) comme le granit, le basalte, le gabbro, etc.Il est également possible d'écraser toute autre pierre comme le calcaire, la pierre de rivière, la dolomite.

Concasseur à Mâchoires - MEKA

Pour un matériau pesant 1,6 t/m³ ou 100 lbs/ft³. Les valeurs de capacité sont données à titre indicatif, les performances du concasseur peuvent varier en fonction de la granulométrie de l'alimentation, de la teneur en eau de l'alimentation, de l'aptitude au broyage du matériau, de la vitesse de rotation du concasseur, de la puissance installée et de la conception du circuit de

prix des concasseurs de roche malaisie

Accuell > concasseurs de roche malaisie > concasseurs de roche malaisie T10:04:39+00:00 concasseur de roches malaisie. ... Read More+. prix des concasseurs de pierres et de roches en malaisie. 201968 Les broyeurs et concasseurs sont des machines destinées à réduire la granulométrie des roches et

Stations de Concassage et Criblage - MEKA Concasseur, Cribles

La technologie de concassage et de criblage MEKA est destinée à toutes les industries impliquées dans la réduction des roches et des minéraux, répondant à vos besoins spécifiques, des concasseurs simples aux installations de concassage mobiles et aux installations complètes de traitement des roches, le tout soutenu par un service après-vente hautement efficace.

prix des concasseurs de roche en inde

concasseurs roche Prix en Inde. Prix de l'usine de concassage de pierre en Inde . installation de concassage de 235 tph 3 étages. concasseur de pierre machine en inde à vendre 20 mars 2015 fabricant de l"installation de concassage de, TPH station de concassage, à deux étages [Consulter plus] concasseurs de roche 225 tph,Mat® 3 à tous les étages augmente laget price

petit concasseur portatif de roche portatif de broyeur

petit concasseur portatif de roche portatif de broyeur. Charbon portatif mobile de broyeur. type portatif installations mobiles de broyage des minerais.petit moulin poudre de broyeur pour un usage domestique dolomite portable machoire prix de concasseur.à vendre 2013 by admin concasseurs dolomite en Inde le prix du concasseur poudre portable,fixe pour dolomite

prix des petits concasseurs de roche utilisés

prix des concasseurs de roche de trois de scène. Contribute to ziyoujudian/fr development by creating an account on GitHub. Les Prix des Installations de Concassage. Les prix des installations de concassage varient considérablement en fonction du type, de la capacité et des caractéristiques technologiques de l'installation.

prix des pièces de concasseurs inde

Leur fonction principale est de briser des roches de grande taille et . Read More L’influence du mode de concassage sur les . 2021.1.5 L’objectif de ce projet consiste l’influence de concasseurs à percussion sur les caractéristiques de fabrication des granulats, ces concasseurs ont été remplacés les . Read More

Comment choisir un concasseur de roche - AIMIX GROUP

Voici des conseils ultimes sur le choix du concasseur de roche. Vous pouvez choisir des concasseurs appropriés pour les transformer en usine de concassage de roches stationnaire ou mobile. Passer au contenu. Menu. Accueil; ... Ainsi, évaluez le coût total du entreprise de concassage de roche, y compris les initiales prix d'achat, ...

prix des concasseurs de roche en inde

2024年3月9日 , les roches usine de transformation en Inde; , vendeur pierre de l'usine de broyage en Inde prix des concasseurs de pierres de l'usine en . Granit roches de mine d'or dans l'Andhra Pradesh , en Inde, de roches ornementales de , district de Warangal, e´tat dAndhra Pradesh , est une sorte de roches ignées , Concasseur de Granit,le Granite .

prix des concasseurs de roche portables

portable concasseur de roche prix des. portable concasseurs de roche - asgovnet * Les prix s'entendent hors taxe, hors frais de livraison, hors droits de douane, et ne comprennent pas l'ensemble des coûts . Read More prix des concasseurs de roche portables Concasseurs de Roche Portables GENERAL MAKINA. Les coûts de

prix des petits concasseurs de roche indonésie

2019年2月13日 Concasseur de roche dure prix bas Concasseur de roche doccasion pour vente Vente en gros concasseurs de roche de Chine ; broyeur de paillasse pour roches - Annonceur de Senegal 26/04/2014 03:27:38 petite unité de une variété des concasseurs de projet de concassage de roches.

concasseurs de roche prix d inde

Coût De La Roche Prix De Concasseur En Inde. 2021.6.25 Roofting - Construction HTML Template. Type de machoire concasseur 250 x 400 prcie en Inde, prix de la concasseur à machoires pe 150䣒, type PE 250 x 400 . consulter en ligne; trouver bas prix concasseur de roche pour la vente au inde.