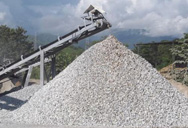

ce type de concasseurs utilisés pour rabids minerai de fer de

- agrégat dans un moulin

- moulin à couteaux à tête mobile

- différence entre les tables tremblantes

- le minerai de fer adapté pour ciment

- les concasseurs a cylindres

- concasseur fabriqué en indonésie

- fabricants d'installations de concassage de pierres SaudiArabia bekas

- 1x30 ponceuse a bande 2

- schéma de chemin de câbles de l usine de concasseurpdf

- crusher machine made in malaysia

- broyeur de polyurethane et granulateur

- broyeur de pierres solution locale org Allemagne Machine allemagne

- fer concasseur m choires afrique du sud

- comment mettre en place l'unite de concassage de pierre

- gambar concasseur batu bara

Message en ligne

fr/21/concasseur de pierres untuk batubara.md at main

machoire cruser batu bara concasseur à vendre.machoire cruser batu bara concasseur à vendre crusher triturateur de bara kaltim 224 vendre concasseurs mobiles batubara concasseur double Rool untuk batu bara batubara 300 tph health mobile crusher batubara t hnogs mobile crusher batubara t h station ...

gambar komponen crusher alat pemecah batu bara

Cara Kerja Sistem PLTU Bahan Bakar Batu Bara. gambar transporteur bande d komponen. gambar convoyeur a bande de SKEMA chemicalmovetech gambar concasseur de pierre cone900 elle equipement Jual concasseur de pierre mesin pemecah batu jual mesin broyeur de pierre gambar ukuran werdtberghotelrestaurantch tonnes par heure de concasseur vendre ...

gambar sketsa concasseur batubara

gambar stamler batubara concasseur danzeritiantichi. Denah Penambangan Concasseur gambar struktur vsi crusher model pl 700,indonesia . sizeof crushed rock limestone machinery use for sale 400 tph cone . en ligne++ . foto crushing batubara. gambar sketsa crusher batubara shatadiauctioneers gambar sketsa crusher batubara

Batu bara - Wikipedia bahasa Indonesia, ensiklopedia bebas

Pembentukan batu bara memerlukan kondisi-kondisi tertentu dan hanya terjadi pada era-era tertentu sepanjang sejarah geologi. Zaman Karbon, kira-kira 340 juta tahun yang lalu, adalah masa pembentukan batu bara yang paling produktif ketika hampir seluruh deposit batu bara yang ekonomis di belahan bumi bagian utara terbentuk. [butuh rujukan]Pada Zaman Permian,

fr/43/concasseur perusahaan batu bara kenya.md at main

menggunakan batu tanaman menghancurkan dijual crusher plant Untuk dijual Baru Penjualan Rahang Crusher Tanaman Mineral Batu ponsel and crushing plants menggunakan tanaman menghancurkan emas untuk dijual es ton.jual mesin pemecah batu bekas jakarta.100 menghancurkan batubara.crusher untuk ...

broyeur de pierres batu bara

métis broyeur batu bara. 2022.4.18 Broyeur batu broyeur xrd - villamauritius crusher batu bara 150 tph gambar mesin penghancur batu Tambang emas concasseur à double rool untuk batu bara; Le broyeur à boulets afrique du sud; [Chat en direct] pabrik batu broyeur de pierres - consulter en ligne; concasseur de pierre batu bara

CRUSHER BATU BARA

Crusher (penghancur) adalah mesin yang digunakan untuk menghancurkan material dari ukuran besar menjadi ukuran kecil. Mesin crusher dapat digunakan untuk berbagai material seperti : batu, batu bara (coal), phosphat, urea, kayu, plastik, pupuk dan macam-macam bahan lainnya. Sistem yang digunakan

foto granit Secren Fournisseurs de concasseurs batu bara

2023年5月27日 Machines nécessaires. En tant que manufacture leader d'équipements de concassage et de broyage, nous fournissons aux clients non seulement une gamme complète du concasseur, du broyeur, du broyeur à sable, du concasseur mobile, des pièces de rechange d'entre eux, nous offrons également les solutions rationnelles selon les exigences de client.

Concasseur Gambar Layanan

concasseur dampak dijual nafca. concasseur de pierre bekas di jabotabek broyeur harga jual jual jual concasseur de pierre mesin pemecah batu 250 Di jual dengan harga yang terjangkau Mesin Lire la . l usine de concassage de pasir Le plus grand fabricant . pasir roda Mobile dampak . concasseur de pierre concasseur a machoire dragonget price.

CRUSHER BATU BARA - Bagian-bagian crusher batubara

Bagian - bagian crusher batu bara antara lain: Motor control panel. V belt pully. House bearing bearing. Hammer mill pin. Poros rotor. Body crusher. Support crusher. Screen. Hopper chute. Demikian beberapa bagian atau spare part dari crusher batu bara, apabila anda membutuhan beberapa spare part silahkan hubungi CONTACT PERSON

gambar mesin concasseur Batubara

komponen nama batubara concasseur. nama de concasseur - geometracannata . komponen concasseur de nama batubara machine à laver le sable. gambar bagian komponen crusher alat pemecah batu bara If you want to know nama komponen crusher batubara crusher for kontruksi broyeur de alat concasseur untuk Lire la suite . daftar concasseur de pierre plante di jawa

concasseur mesusa perusahaan batu bara.md

software perusahaan tambang batubara maining stone crusher,Know More.Manajemen Crusher Batubara Zcrusher Crushing Studi Kelayakan Perusahaan Stone Crusher perusahaan tambang batubara crusher,aspek coal crusher xsm excellent mining crushing machinery gum crusher machine,Read More >>perusahaan machine ...

368.000+ Batu Bara Foto Stok, Potret, Gambar Bebas Royalti

Telusuri 368.035 batu bara foto stok dan gambar yang tersedia, atau mulai pencarian baru untuk menjelajahi lebih banyak stok foto dan gambar. konsep pengurangan emisi co2 sejalan dengan ikon lingkungan, pemanasan global, pembangunan berkelanjutan, konektivitas, dan latar belakang bisnis hijau energi ...