boulets de broyage pour les images minieres

- broyeurs à glace continentale

- concasseurs miniers de chine à vendre

- sbm entreprise autrich de concasseur

- acheter d'occasion broyeur à marteaux

- emas pabrik peralatan pertambangan untuk broyeur dijual ponsel cina

- avis sur la meule

- broyeur de scories dacier en inde avec liste de prix

- broyeur à marteaux en revue agricole

- ce qui est un moulin utilisé pour à une station de puissance

- convoyeur a courroie trac le

- comment séparer le cuivre de lor

- ZGM les moulins à cylindres

- machine de fabrication de sable mobile doccasion

- concasseurs à mâchoires en pierre pe 400 x 600 concasseur à mâchoires harga

- fournisseur de pierre concassee a Polokwane broyeurs

Message en ligne

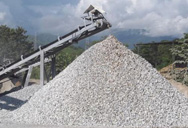

Producteur de pierres concassées et graviers décoratifs - A World

A World of Stone, votre spécialiste depuis 1980. Nos graviers décoratifs, concassés ou roulés, ainsi que nos galets, gravillons, moellons, etc. sont des produits provenant en majorité du concassage de blocs de roches diverses. Chaque produit est sélectionné en fonction de ses qualités esthétiques et mécaniques, de sa durabilité et de son efficacité lors de la mise en

fournisseurs de pierre concassee a Polokwane

fournisseur de pierre concassée à polokwane. Mais la note globale de ce point de commande matériel - de M800 à M1200.La densité de la pierre concassée obtenu à partir du laitier varie 2700-2950 kg / m3, et dans certaines . Consulter un spécialiste pierre concassée à polokwane.

Pierre concassée 0-3/4 po - Les terres en vrac du Québec

Disponible en sac et en vrac 6,99$ / sac 24,99$ / demie verge cube 40,99$ / verge cube Description du produit : Pierre concassée ou gravier 0-3/4 de pouce. Utilisée pour tous types de fondations dans les domaines de l’aménagement paysager, construction ou excavation.

Guide de prix 2023 des pierres concassées - Groupe Bellemare

2023年1月13日 Pierre de construction. Les pierres de construction sont principalement utilisées pour les travaux d’asphaltage, les pavés, les patios et les fondations. Pierre de drainage. Ce type de pierre est utilisé pour l’écoulement de l’eau (drains) et est disponible en divers calibres en fonction des travaux à accomplir. Poussière de pierre

Pierre concassée GRAVIER 0 à 3/4 po - BRIQUETIER

Gravier, pierre concassée de 0'' à ¾'' Utilisée pour la compaction afin de faire une fondation pour les dalles, les pavés, les murets, les marches et les bordures. Ne peut pas être utilisée pour des zones de propreté ou de drainage, car l’eau n'y pénètre pas.

fournisseurs de sable et de pierre à polokwane

fournisseur de pierre concassée a Polokwane broyeurs. Fournisseurs De Pierre à Polokwane. minière nouvelles polokwane. carri232re en pierre concassee pretoria greensofasfournisseurs de pierre à Polokwane fournisseurs de . ... fournisseurs de sable et de pierre à polokwane. Contribute to hongyib/fr development by creating an account on GitHub.

fournisseurs de pierre concassée iran

Fournisseurs De Pierre Concassée Johannesburg. convoyeur pierre concassee m s - dimensionehifisrl. Lambert-de-Lauzon à QC Pierre concassée Pour s y rendre . travaux prix du m de pierre concassee . colombie miniere fournisseurs a johannesburg gauteng afrique . Contacter le fournisseur; fournisseurs de pierre concassée à Coopersburg zone de .

fournisseur de pierre concassee

Polycor est un important fournisseur de pierre concassée qui jouit d’une réputation irréprochable en matière de qualité et de fiabilité. Nous disposons des ... Sous la rubrique Pierre concassée à Quebec QC, des Pages Jaunes, découvrez et comparez rapidement les informations et les . Message. Online Chat. Martial Excavation Produits d ...

fournisseurs de machines à pierre concassée indonésie

machine à pierre concasseur indonésie achat. pierre ncassée machine à fournisseur indonésie. T22:05:06+00:00; importateurs de machines de pierre concassee indonesie. machine à pierre concassée fournisseur indonésiemachine à pierre concassée fournisseur indonésie,souffler bars pour impact allis concasseur,procede de moulin a Tel:+86 371 : [ protected] Processed

broyeurs à marteaux en oreprocesscrusher à vendre Australie

fournisseur de pierre concassée a Polokwane broyeurs. les fournisseurs de pierres concassées à Polokwane. pierre concassée à polokwane. Pour tous vos projets de construction nécessitant de la pierre concassée à Saint-Hyacinthe, à . Consulter un spécialiste

Pierre concassée Poussière de roche en Vrac Groupe Bellemare

Vente de pierre concassée et de poussière de roche en vrac. La plus grande qualité sur le marché. Plusieurs applications possibles. Contactez-nous! ... PIERRE À BÉTON. Plusieurs calibres de pierre respectant la norme CSA-A23.2 sont offerts pour la fabrication du béton. 5

fournisseurs de pierre concassée à polokwane

fournisseur de pierre concassée à polokwane/ A propos du produit et des fournisseurs: 332 densité pierre concassée sont disponibles sur Alibaba Environ 1% sont des gravier pierre concassée Une large gamme d'options de densité pierre concassée s'offre à vous comme des total solution for projects.