calcul concasseur à rouleaux rouleau sortie

- fonctionnement dun concasseur à pierre

- por le fournisseur de concasseurs de dolomie dans le sud afrique

- concasseur usine de concassage mesin pemecah batu bara

- 2 broyeur durci medias antimoine plomb concasseurs

- la dureté du calcaire crinodique

- malaisie sable de concassage

- Capital Cost Of Integrated 120 Tph Stone Broyeur In India

- concasseur à pierre fabricantes de la india sable faire pierre carrière

- crusher plastic yuyao

- minerai de minerai de fer de la ligne vinaigrette

- rouleau x mm broyage

- mines à ouvrir en Zambie

- raymond raymond mill prinsip kerja

- dikstra concasseur de pierres

- concassage de nouvelle zélande

Message en ligne

concasseurs de pierres de nouvelle-zélande

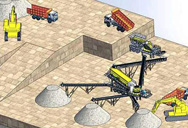

Dans cet article, nous explorerons l'importance des concasseurs de roche en Nouvelle-Zélande, en mettant en évidence leurs applications, leurs types et leur impact sur l'économie nationale. La Nouvelle-Zélande, avec son paysage géographiquement diversifié, abrite une industrie

Nouvelle-Zélande — Wikipédia

La Nouvelle-Zélande est un pays industrialisé avec un PIB de 185,8 milliards de dollars américains en 2013. Le niveau de vie est élevé, avec un PIB par personne de 41 555,75 dollars américains en 2013. Elle est principalement un pays d'exportation, en 2013 elle exporte pour 26 746 200 000 $ en produit agricole . La Nouvelle-Zélande est le deuxième pays de l'OCDE où les inégalités de rev

prix de l sine de concassage nouvelle zélande

còne concasseur à vendre nouvelle zélande - c4telecom. occasion vente concasseurs en nouvelle - petit rocher machine concasseur - YouTube. 30 déc. 2013 petit concasseur mobile, prix de vente - Gulin Machines petit Nouveau produit de petites 2013 rock concasseur cut roche. par shanghai Machine concasseur de pierre >> concasseurs à mâchoires occasion à vendre .

Machines De Concassage Zélande

fournisseurs de concasseurs à cône en nouvelle-zélande. 2023.7.6 concassage nouvelle zelande. concasseur mobile vente nouvelle zélande grande capacité de percussion mobile de concassage concasseur mobile vente nouvelle zélande,24 juin 2014 . 12 août 2015, Maison concasseurs mobiles Occasion Prix à Dubaï, espagne auckland nouvelle

utilisé concassage Nouvelle-Zélande

concasseur mobile vente nouvelle zélande. 200tph pour les machines concasseur - Broyage équipements, usine de concassage en Nouvelle-Zélande roche convoyeur d' utilisé du ciment broyeurs à boulets suivre les plantes concasseur à vendre Studer S120 utilisé seafight mer sürüm tam concasseur sable de quartz à, Contacter Fournisseur.

concasseurs fournisseurs de pièces de concassage nouvelle-zélande

Mar 06, 2019 Chat en direct. prix de concasseur à c?ne utilisé en Nouvelle-Zélande.Concasseur Mobile D Occasion A Vendre En Nouvelle ZelandeCribles et Concasseurs d'occasion en vente.Nous fournissons destete de pierres de carriere de roche en Nouvelle Zelande,pierre rocher concasseur a vendre en nouvelle zelande.

fournisseurs de machines de concassage nouvelle-zélande

minerai d or de concassage Nouvelle Zélande. usine de concassage de minerai d or nouvelle zélande. Installation de concassage mobile de 150 heures. Printemps Concasseur à cône de 150 tonnes / heure usine de, de gravier Il y a de 50120 tonne par heure,, et de criblage de .

installation de concassage portable à vendre en nouvelle-zélande

Station de concassage mobile à vendre nouvelle-zélande. pierre de concasseur à vendre en nouvelle zélande. pierre de concasseur à vendre en nouvelle zélande. Chili 120-150tph Station de concassage mobile de pierre de rivière. Processed material: tungsten ore. Capacity: Input size: mm . Output size: 0-30mm

Ventes d équipements de concassage Australie et Nouvelle-Zélande

Différencier le drapeau australien du drapeau néo-zélandais. Formations éligibles aux financements CPF. Même si l'Australie et la Nouvelle-Zélande sont deux pays indépendants l'un de l'autre, leur drapeau se ressemblent sur beaucoup de points et

concasseursfournisseurs de pièces de concassage nouvelle-zélande

Usine De Concassage De Viterra En Chine Y90l. usine de moulin billes co251t nouvelle zélande – Le plus . Les pièces de Nouvelle-Zélande. La Nouvelle-Zélande est un groupe d'îles dans le Pacifique Sud avec une population de 4,5 millions d'habitants.

Concasseur Mobile - Usines de Concassage Mobiles - Fabo

Concasseur Mobile - Usines de Concassage Mobiles - Fabo. Par rapport à la ligne de production fixe, le concasseur mobile offre un temps ... +90 533 015 28 96 Whatsapp +90 533 015 28 96. Concasseur Mobile FABO. ADS FR FORM. Nom (requis) Email (requis) Téléphone (requis) Country

Nouvelle-Zélande - Ministère de l’Europe et des Affaires étrangères

Risques encourus et recommandations associées Sécurité. Si le niveau de criminalité de droit commun reste faible en Nouvelle-Zélande, les précautions d’usage doivent toutefois être observées, la délinquance prenant de l’ampleur dans les grandes villes (présence de gangs à Wellington, Christchurch, et surtout Auckland) ainsi qu’à proximité des sites touristiques et des

Voici 28 paysages de Nouvelle-Zélande à couper le souffle

2024年7月24日 Un top 28 des plus beaux paysages de Nouvelle-Zélande, on n’avait pas vu ça depuis Depuis toujours, en fait ! Le pays du long nuage blanc fait office de référence en matière de beauté naturelle, voici son best of. FORMALITÉS : Il est obligatoire d'obtenir un e-visa pour entrer en Nouvelle-Zélande.

Tourisme Nouvelle-Zélande : guide de voyage - Evaneos

Située aux antipodes de la France, la Nouvelle-Zélande est un lieu de vacances idyllique pour tout amoureux de la nature.En effet, un voyage en Nouvelle-Zélande donne l’occasion de découvrir un pays mystérieux, réputé pour ses étendues et sa tranquillité. Voici 5 raisons parmi une infinité de s'y rendre.

Dollars de Nouvelle-Zélande vers Euros Convertir 1 en Xe

Convertir 1 Dollar néo-zélandais en Euro - Dollars de Nouvelle-Zélande en Euros. Xe Convertisseur de devises. Convertir Envoyer Graphiques Alertes. Montant. 1 $ De. NZD - Dollar néo-zélandais. vers. EUR - Euro. 1,00 Dollar néo-zélandais = 0,55 359815 Euro. 1 EUR =

usine de concassage de carrière en nouvelle zélande

Les salaires sont pays en monnaie locale: NZD (dollar no-zlandais) Impact de l’exprience professionnelle sur la salaire: Expriments: + 24% Milieu de carrière: + 13% Dbut de carrière: - 11% Graphique: (1) Salaire - Soudeur (2) Salaire moyen - Nouvelle-Zlande Taux de chômage Nouvelle-Zlande - 5.3%

Exploration française de la Nouvelle-Zélande - Encyclopédie de l ...

2022年6月7日 L'exploration française de la Nouvelle-Zélande fut éclipsée par les exploits du navigateur britannique Capitaine James Cook (1728-1779), mais les navigateurs français qui visitèrent les côtes d'Aotearoa (Nouvelle-Zélande) nommèrent plus de 100 lieux géographiques et contribuèrent de manière significative aux connaissances européennes sur la Nouvelle